Why Your Garage Door Motor Deserves Your Attention

When you need to repair garage door motor issues, it can be a major frustration. Your garage door motor is one of the hardest-working components in your home, opening and closing over 1,500 times per year. A sudden failure can turn a simple commute into a stressful ordeal.

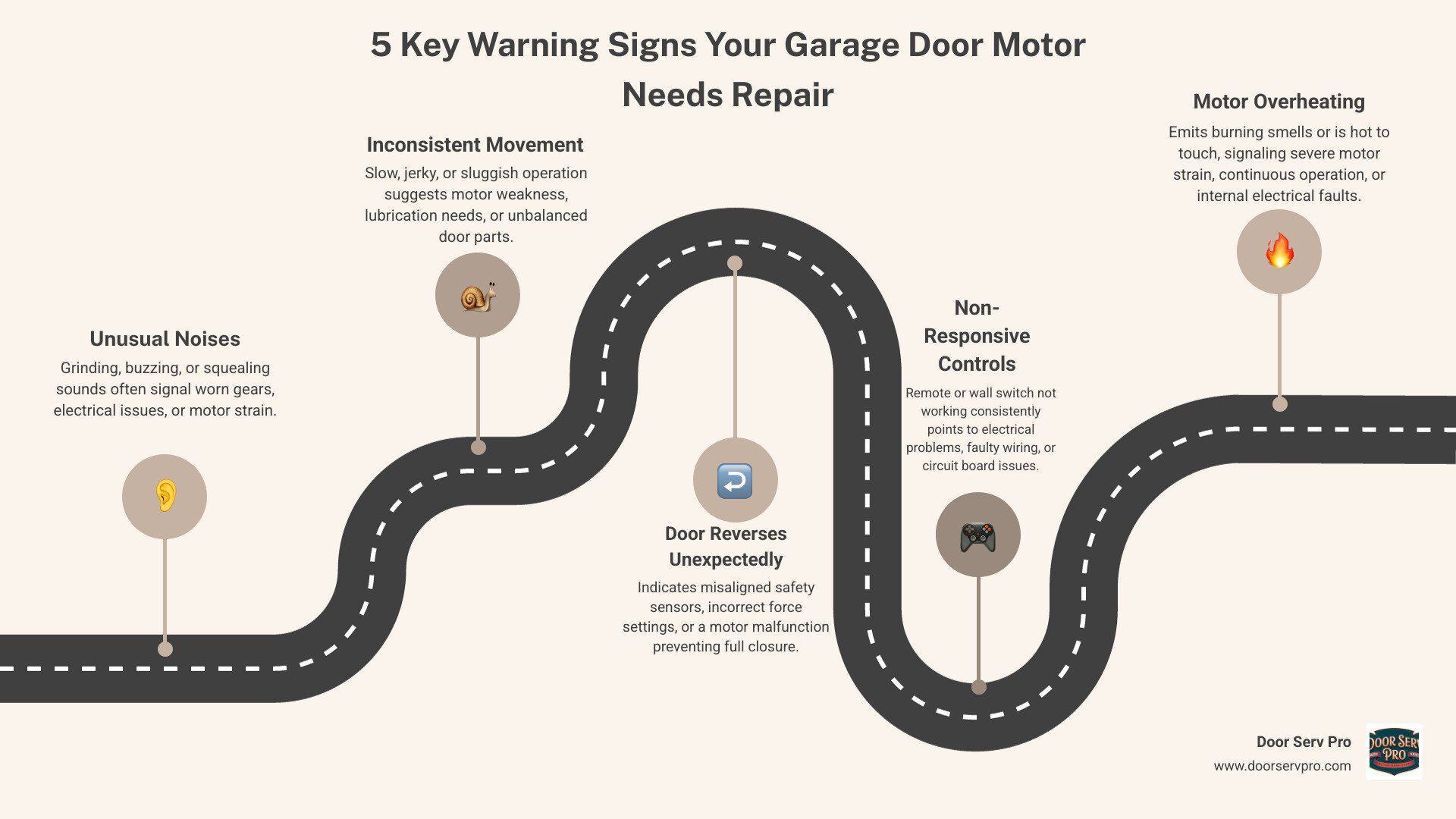

Quick Signs Your Motor Needs Repair:

- Grinding or buzzing noises during operation

- Slow or jerky movement when opening/closing

- Door reverses unexpectedly before reaching the ground

- Remote or wall button stops responding consistently

- Motor overheats or emits burning smells

The good news is that many motor problems can be repaired without replacing the entire system. With a typical lifespan of 10-15 years, knowing when to repair versus replace can save you hundreds. Most motors fail gradually, giving you warning signs before a complete breakdown. Recognizing these symptoms early allows you to address issues before you’re stranded or your home’s security is compromised.

This guide covers everything from identifying motor problems to deciding between DIY fixes and professional repair, helping you keep your garage door running smoothly.

Is Your Garage Door Motor Failing? Key Warning Signs

Most homeowners don’t think about their garage door motor until it fails. Fortunately, most motors provide clear warning signs before they stop working completely.

Unusual noises are often the first indicator of a problem. Grinding sounds typically mean the internal gears are worn from friction. Squealing or buzzing often points to electrical issues, like a failing capacitor or circuit board problem. These sounds are your motor’s cry for help.

Inconsistent movement is another red flag that it’s time to repair garage door motor issues. You might notice jerky operation instead of a smooth glide, or the door may become sluggishly slow. Other frustrating symptoms include the door reversing unexpectedly or the remote and wall switch becoming unresponsive. If the motor overheats or you smell something burning, stop using it immediately and call a professional, as this is a serious safety risk.

Diagnosing Strange Noises

Each sound your motor makes can help diagnose the problem.

Grinding indicates worn gears inside the motor. Over time, plastic or metal gears can strip, creating a grinding sound as they struggle to engage.

Buzzing suggests electrical issues, such as a faulty start capacitor or circuit board. The motor receives power but can’t start moving the door.

Clicking points to a relay problem on the opener’s logic board. You’ll hear the click, but the motor won’t engage.

Rattling could be a loose chain or hardware that needs tightening. While not a direct motor problem, it forces the motor to work harder.

Performance-Related Symptoms

Performance issues can also signal a failing motor.

Slow operation is a common sign of a struggling motor, which may be compensating for worn components or other issues like failing springs.

Intermittent stops during operation mean the motor is straining to lift or lower the door.

Incomplete opening or closing often points to misaligned limit switches, which tell the motor when to stop.

Failure to lift the door while the motor runs is a classic sign of a stripped drive gear. The motor spins, but it can’t transfer power to the chain or belt.

For more detailed information about garage door opener troubleshooting, more info about garage door openers can provide additional manufacturer-specific guidance.

Understanding Your Opener: Motor Types and Common Problems

To repair garage door motor issues effectively, you must first understand your opener type. Like car engines, garage door motors vary in design, each with unique characteristics.

AC motors, found in older units, are powerful but noisy. DC motors are common in newer models, offering quiet operation and features like soft start/stop and battery backup.

Horsepower (HP) is also crucial. A ½ HP motor is fine for most single doors, but heavier wood or insulated doors require ¾ HP or 1 HP to avoid straining the motor.

| Motor Type | Noise Level | Maintenance Needs | Typical Cost |

|---|---|---|---|

| Chain-Drive | High | Regular lubrication, chain tension checks | Lower |

| Belt-Drive | Low | Minimal; belt checks for wear/slipping | Medium |

| Screw-Drive | Medium | Twice-yearly lubrication; sensitive to temperature | Medium |

Chain-Drive Openers

Chain-drive openers use a metal chain to move the door. They are known for their reliability and affordability but are also the noisiest option. The metal-on-metal contact creates a loud, rumbling sound.

Common issues include the chain stretching over time, which causes jerky movement and requires tension adjustments. The internal drive gears and sprockets also wear down from constant use, leading to grinding noises.

Belt-Drive Openers

Belt-drive openers use a reinforced rubber belt, resulting in nearly silent operation. This makes them ideal for homes with living spaces above or near the garage. They are more expensive upfront, but many homeowners find the quiet performance worth the cost.

Common issues are straightforward. The belt can slip if it loses tension or wears out, and it may eventually break after many years of service. These models often include modern features like Wi-Fi connectivity and battery backup.

For detailed specifications on popular opener models and their features, you can check out information on popular opener models.

Screw-Drive and Direct-Drive Openers

These designs feature fewer moving parts. Screw-drive openers use a threaded steel rod, while direct-drive systems place the motor in the trolley that moves along the track. Fewer parts generally mean less maintenance.

Common issues for screw-drives are often temperature-related. The lubricant on the threaded rod can thicken in the cold or thin out in the heat, affecting performance. Twice-yearly lubrication is critical to prevent this. Even with fewer parts, the drive gear inside the motor can still wear out, causing the motor to run without moving the door.

A Step-by-Step Guide to Basic Garage Door Motor Repair

When it’s time to repair garage door motor issues, many homeowners feel intimidated. However, many common problems can be fixed with basic troubleshooting and proper safety precautions. Garage door systems are heavy and involve high-tension springs and electricity, so caution is essential.

Think of this as a detective process. Sometimes the “motor problem” isn’t the motor at all but a simpler issue like a misaligned sensor or a dead remote battery.

Essential Safety Precautions for DIY Garage Door Motor Repair

Safety is non-negotiable when working on garage doors. Many accidents are preventable with the right precautions.

Unplugging the opener is the first and most important step. Disconnect the power cord from the outlet to prevent accidental activation.

Securing the garage door is next. If the door is open, clamp it to the track with C-clamps or locking pliers to prevent it from falling.

Wearing safety glasses protects your eyes from debris, dust, and lubricants when you’re looking up at the opener.

Be aware that capacitors can hold electrical charges even after the power is off. These components help start the motor and can deliver a shock. Avoid touching electrical components inside the motor housing if you’re unsure.

Most importantly, never attempt to work on springs or cables. These parts are under extreme tension and can cause severe injury or death. If you suspect a spring or cable issue, stop immediately and call a professional.

Troubleshooting Common Issues Before You Repair Garage Door Motor

Many apparent motor failures are simpler problems. Eliminate these easy fixes first.

Remote battery problems are a common culprit. If the remote doesn’t work, try fresh batteries before investigating further. If the wall button also fails, the issue is with the opener itself.

Safety sensor misalignment is a frequent cause of service calls. These photo-eyes create an invisible beam that, when broken or misaligned, prevents the door from closing. Check for solid lights on each sensor (usually green), clean the lenses, and gently adjust them until the lights are steady.

Limit and force settings control the door’s travel distance and power. If your door stops short or reverses before closing, these settings may need adjustment. Your owner’s manual provides instructions for turning the adjustment screws.

Stripped drive gears are indicated by the motor running but the door not moving. This plastic gear connects the motor to the drive system and is a common part to fail. Replacement gears are available for most brands.

Start capacitor failure often causes a buzzing or humming sound as the motor tries to start but can’t. This component gives the motor the initial boost it needs. Replacing a capacitor requires electrical knowledge, so call a professional if you’re uncomfortable.

Repair vs. Replacement: Making the Smart Choice

When your garage door motor acts up, you face a key decision: repair garage door motor issues or buy a new opener? The right choice depends on a few factors.

Most motor repairs, like replacing a drive gear or capacitor, are cost-effective and can add years of life to your opener. However, the age of your motor is a critical consideration. A quality opener lasts 10 to 15 years. If yours is approaching that age, frequent repair bills can quickly add up, making replacement a smarter investment.

When to Repair Your Motor

Repairing makes sense for isolated problems on younger openers. If your motor is under 10 years old and has its first major issue, a fix is usually the best option.

- Minor part failures: A single failed component like a drive gear or start capacitor is a straightforward repair.

- First-time issues: If the opener has been reliable until now, it likely has more years of service left after a repair.

- Adjustment problems: Issues caused by misaligned sensors or incorrect limit/force settings are simple adjustments, not true motor failures.

When to Replace the Entire Opener

Replacement is often better for older openers with recurring problems.

- Age: If the opener is over 10 years old, other components are also likely near the end of their lifespan. Investing in a new unit can be more economical in the long run.

- Multiple problems: If the motor is noisy, the sensors are failing, and the remote is unreliable, the entire system is likely worn out.

- Obsolete parts: Manufacturers eventually stop making parts for older models, making repairs impossible.

- Technology and safety: Newer openers offer Wi-Fi connectivity, battery backup, and improved safety features that older models lack. Upgrading can improve both convenience and security.

The Professional Advantage vs. DIY Repair

While understanding your garage door system is valuable, there’s a significant difference between diagnosing a problem and attempting to repair garage door motor components yourself. DIY repairs seem cost-effective, but they come with serious risks.

Garage doors are heavy, and their springs are under extreme tension, posing a significant safety hazard. Modern openers are also complex, with circuit boards, sensors, and precise calibration needs. A small mistake can void a warranty, damage other parts, or create a new safety issue.

At Door Serv Pro, our NATE-certified team brings over 25 years of expertise to every job. We often find that fixing a DIY repair attempt costs more than the original professional service would have. Trusting a professional from the start is the safer, more reliable choice.

Benefits of Hiring a Professional

Choosing Door Serv Pro for your garage door motor repair provides peace of mind and guaranteed results.

- Guaranteed Workmanship: We stand behind our work with a warranty on parts and labor, backed by our 100% satisfaction guarantee.

- Accurate Diagnosis: Our experienced technicians quickly identify the root cause of the problem, saving you from expensive guesswork.

- Time and Frustration Savings: We arrive with the right tools and parts to get the job done efficiently, saving you the hassle of a prolonged DIY project.

- Safety Compliance: We ensure all safety features are correctly calibrated and that the repair meets manufacturer specifications and local codes.

- Access to High-Quality Parts: We use manufacturer-approved components for durable, long-lasting repairs.

At Door Serv Pro, we don’t just fix doors—we create lasting impressions, one entryway at a time. Our family-owned business has been proudly serving WV, VA, PA, and MD for over 25 years, and we bring that experience to every repair garage door motor job we tackle.

Conclusion

This guide has covered the key aspects of repair garage door motor problems, from identifying warning signs to deciding between repair and replacement. The most important takeaway is that safety always comes first. The high tension in garage door springs and cables makes them dangerous for anyone but a trained professional to handle.

Your garage door is essential for your home’s security and your daily routine. Addressing motor issues promptly prevents minor annoyances from becoming major problems. Whether you’ve diagnosed the issue or realized it’s more complex than you thought, you now have the knowledge to make an informed decision.

For expert assistance and guaranteed results, trust the certified team at Door Serv Pro. Founded by industry veteran Paul Wiese, our family-owned company has served WV, VA, PA, and MD for over 25 years. We combine technical expertise with a personal touch that comes from decades of experience.

Our NATE-certified team offers a 100% satisfaction guarantee and round-the-clock service. We understand that garage door problems happen at inconvenient times, and we’re here to help whenever you need us.

At Door Serv Pro, we believe every home deserves to function beautifully and safely. We don’t just fix doors—we create lasting impressions, one entryway at a time.

Schedule your garage door opener repair in Frederick, MD today.